On the 8th August, we took part in 24 Hours in Farming, the agricultural industry’s biggest online event, which highlights the pride of the nation’s food producers and encourages farmers to show the general public a typical working day through the power of social media using the hashtag #Farm24. Starting at 5am on Thursday 8th and finishing at 5am on Friday 9th, this 24 hour event encouraged British farmers to share an insight into their day to show consumers the effort and care that goes into producing their food.

Duncan Farrington ready for #Farm24

Starting first thing in the morning, Duncan had to move all the barley in the barn back as far as possible, to give plenty of room for the barley he was due to the harvest throughout the day.

View from inside the combine harvester

Meanwhile, Robert (Duncan’s father) and Marvin (our farm worker) started preparing the combine harvester. This involved cleaning the windscreen, blowing the dust from the combine to reduce fire risk, setting up the GPS and getting the combine ready for a busy day. Once everything was set, Marvin starting combining. We use GPS to pinpoint our location in the field and steer the combine through the field, ensuring that each length of the field is harvested as efficiently as possible, reducing fuel usage and taking less time.

We were harvesting spring barley on this particular day. This year our spring barley was destined to be made into malt for beer, so a fairly important crop in our opinion!

Barley being unloaded into the trailer

Whilst Marvin drove the combine, Duncan and Robert took it in turns to fill a trailer load of harvested barley from the combine and take it back to the farm yard and tip it into the barn. By having both Duncan and Robert do this, they were able to keep up with the speed Marvin was harvesting at so the combine didn’t have to stop at any point.

Cover crop seeds – buckwheat & phacelia

We visited another field on Bottom Farm, this one was harvested a few days previously and then planted with cover crops. We use cover crops to improve the health of our soil, but the key benefit is the fact that they absorb CO2 from the atmosphere and store the carbon in the soil (more info here). We planted buckwheat (the bigger, pyramid shaped seeds) which scavenge for phosphate and helps young plants’ root development. We also planted phacelia (the tiny seeds) which have fibrous roots for soil structure. On the same day as #Farm24, the UN also released their latest climate change report, which highlighted the importance of soil and storing carbon from the atmosphere in soil, which is exactly what our cover crops do!

Whilst Duncan was busy with harvest, his wife Eli jumped in a tractor and rolled the fields of cover crops. Rolling smooths the field and ensures the seeds are pushed into a good soil base to give them the best chance for growing.

Eli Farrington in tractor

Next, we headed over to the Mellow Yellow production barn. Mellow Yellow Rapeseed Oil is grown, pressed and bottled on the farm. First of all, the seeds go into big yellow hoppers which feeds the seed into the presses. The seed is then cold pressed which involves being gently squeezed until the yellow oil is released. The seed husk is not wasted, it is shaped into pellets and sold to local farmers as high quality animal feed for cattle, pigs and sheep.

Rapemeal

Rapeseed oil dripping from press

Once the seed has been pressed, the oil trickles out and is simply passed through a filter, a bit like coffee paper, before it is put into bottles. These bottles were then destined for Morrisons, the sponsors of 24 Hours in Farming, a lovely coincidence!

Returning back to the combine harvester, Duncan, Robert and Marvin had lots of barley to harvest, so ended up going until half 10 that night, it’s a good thing the combine has headlights! By the end of the day, we had managed to harvest all the barley, which we were VERY pleased with, especially as rain started to fall the minute after we had shut the combine into the barn, perfect timing or what! The weather often causes problems around harvest, the crops may be ready but if it’s raining, we can’t combine as the moisture levels must be low.

Duncan, Robert and Marvin after a busy day’s harvesting

Throughout the day, hundreds and thousands of British farmers and food producers shared images and videos from their day with #Farm24. It was a fantastic day for learning about how our food is produced. #Farm24 was trending for most of the day and over 8 million people saw the photos and videos shared throughout the day! For more information on 24 Hours in Farming, please visit Farmer’s Guardian here: https://www.fginsight.com/24hoursinfarming/sponsored—24hoursinfarming

Bottom Farm is an arable farm, in other words, we grow crops and not animals. However, when giving talks on sustainable agriculture, I sometimes say that we do have livestock on Bottom Farm in the form of worms, pollinating insects, beetles and a whole host of other beneficial little creepy crawlies that help me grow my crops. They help by recycling old plant debris to create plant food for the growing crops in the case of worms; or pollinating our rapeseed and beans in the case of pollinating insects; or indeed helping with my pest control, in the case of the beetles that eat unwanted aphids on the crops. But in the more traditional sense, we don’t usually have livestock on the farm.

As part of a good sustainable farming system, I grow a healthy rotation of different crops around the farm each year. The basis of this being that different crops take different things from the soil and put different things back. In addition to growing different crop types, we also plant crops at different times of the year which helps in breaking weed and disease cycles. Generally, we plant crops in either the autumn or the spring.

Before planting a spring crop of say, barley, I plant a cover crop in the autumn. A cover crop does just as it says, it covers the ground, protecting the soil from winter rains. By growing a crop throughout the winter months means the growing roots are holding onto precious minerals rather than being washed away in the rainfall. The roots also keep the soil in good structural condition, keeping it lovely and friable for the following spring crop. Finally, the growing crops provide a food source for all those little creepy crawly animals and bacteria in the soil that work altogether to make a healthy fertile soil.

I have tried several different crops over the years and currently favour a mixture of crop species, this includes oats, vetch, phacelia and buckwheat for example, each adding their own little bit of magic to the mix. Generally, I plant the cover crops in August or September and allow them to grow until January or February. As soon as the weather conditions allow, we will apply a herbicide to the crop to kill it off, giving it time to die and breakdown in readiness for the spring barley to be planted in March or April. By giving time for the crop to breakdown, all the bugs in the soil will start converting some of the plant material into nutrition ready for the new planted barley to feed on and grow healthily into a crop to be harvested.

However, let’s return to the topic of livestock on Bottom Farm! Over the last few years, on some of the cover crop fields I have used sheep to graze off the vegetation in readiness to plant the following crop. This traditional method of destroying the cover crop is sometimes called the ‘golden hoof’, as the sheep not only remove the crop, but in the process, convert it into a fresh source of manure, thereby fertilising the soil. The sheep are not mine, but belong to a local farmer who takes them from farm to farm, where he gets good quality grazing for his flock, whilst providing us with an excellent lawnmower and fertiliser service. It does mean for a few weeks a year, I become a livestock farmer and we have sheep on Bottom Farm. I thoroughly enjoy walking the field every morning to check they are all still there and happily grazing. You could say it makes me feel like a real farmer, using traditional methods in our very modern world.

You can learn more about our sustainable farming practises here.

Duncan Farrington

“A nation that destroys its soils destroys itself”

Franklin D Roosevelt.

As a farmer, I have always known that everything I produce is dependent on the soil I grow my crops in and the rain that falls on them. Without these natural resources, we would fail. However, it is not just farmers that soils are important to. They are the cornerstone for the survival of life on earth and, as former American President Roosevelt appreciated, the key to the prosperity of whole nations and civilizations.

Ever since mankind turned from hunter gatherer to farmer, we have had the sad record of destroying our soils, which led to the demise of empires. Whether this being the Ancient Greeks, where ancient monuments are now surrounded by arid bedrock, in what was once fertile farm land. Or the fall of the Roman Empire, which spread out north and south from Italy, in the attempt to bring food in from new agricultural lands. Or more recently the fall of the Soviet Union, as the population got fed up with constantly queuing for essential staple foods, where in reality they were not producing enough food to feed themselves.

In nature crops and animals grow naturally quite well, but they are a bit randomly spread out. As mankind started to domesticate crops and animals for their needs, they started clearing areas of land to produce more food in a given area. The land was cultivated by the plough, originally a small implement pulled by an ox or donkey, today it is much larger and pulled by tractors. But the principle is the same. The plough turns over and breaks up the soil surface to create a seed bed to plant crops in. The advantages are that it provides soils free from weeds, provides good conditions and soil structure for plants to grow in. It also gives a nutritional boost to the plants as bacteria breakdown minerals for the plants to feed off.

Over time the disadvantages of ploughing however outweigh the advantages. The freshly disturbed surface of the earth is very fragile, especially when it rains, with soil erosion being particularly noticeable on slopes. As rain drops hit the soil surface, water drains down-hill into streams, rivers and eventually into seas and oceans. But the water takes the fertile soil particles with them, which in time can remove the soil completely; think of those ancient Greek monuments standing on top of rocky outcrops. But it still happens today as this satellite image of the UK clearly shows. Now whilst I am all for us exporting more products to our friends in Europe, I am not sure we want to be sending them our fertile soil.

This satellite image, taken on 16 February 2014, shows how soil is washed off our fields and out into the sea. ©NEODAAS/University of Dundee

Also, whilst ploughing creates a lovely loose structure for seeds to germinate in, the action of ploughing exposes the soil to oxygen in the atmosphere. This gets all the soil bacteria really excited, similar to a young child being given sugary sweets, running around really quickly, before collapsing in a heap on the floor once the sugar rush is over. The bacteria ‘run around’ in this high oxygen atmosphere, giving lots of nutrition to the crop, but it is short lived as the bacteria eat up the store of carbon in the soil, respiring as they do so, and thus release the stored carbon to the atmosphere as carbon dioxide. This has the double negative effect, of gradually reducing the nutritional content of the soil and increasing the global warming effects of increased CO2 in the atmosphere.

Having learnt much on soil quality over the years, I took the decision not to plough on our farm back in 1998. Admittedly, my incentive was not just to save the planet, but also to save money as ploughing is an expensive operation. Although it was known my crop yields could reduce a little, hopefully this would be more than compensated by reduced costs. When I stopped ploughing, I made lots of mistakes as yields reduced dramatically for a short period, as well as weed pressure increasing. Our neighbours thought I was a bit daft – they may be right on that one. But over the years, I have learnt an awful lot as the system has improved. The theory of not ploughing is that naturally plant roots and creatures like worms improve soil structure. The bacteria and other micro fauna improve the soil health and biology, converting old plant residues and mineral content of the soil into plant food. So by not ploughing, the soil structure and organic matter content gradually improves year on year and, the carbon from the soil is not released to the atmosphere as CO2. I continue to learn from my experiences as we are making a healthy environment for the plants to grow in, but this is the underlying theory.

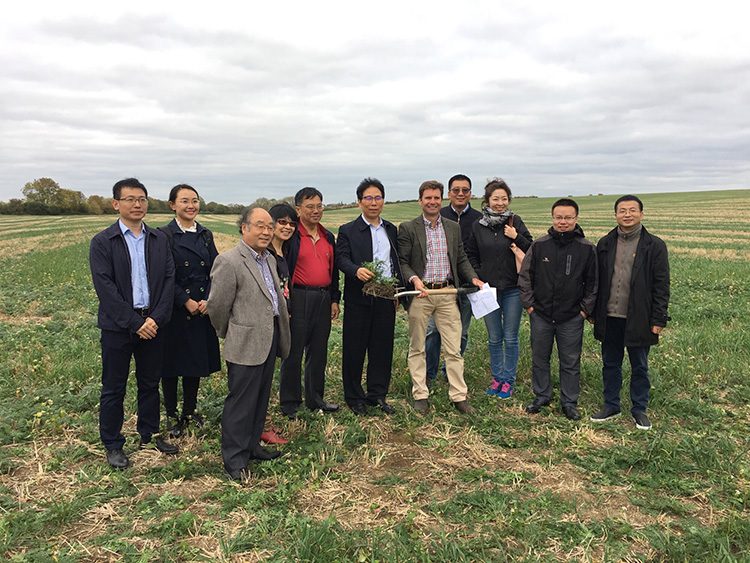

Delegation from China, including Deputy Director General of the Ministry of Agriculture and the Chinese delegate for the United Nations Environment team.

Today, soil health is something that governments around the world are realising is important and we should be doing something to improve our most important natural asset. I was especially proud recently when, along with LEAF, I hosted a delegation from China which included; The Deputy Director General of the Ministry of Agriculture and the Chinese delegate for the United Nations Environment team. They were very interested in what we are achieving with our soil health on the farm.

Plenty of commentators accuse agriculture of being a huge cause of global warming from CO2 emissions, however I can show from what we are doing on our farm, agriculture can play a major role in reducing CO2 emissions when looking after our soils.

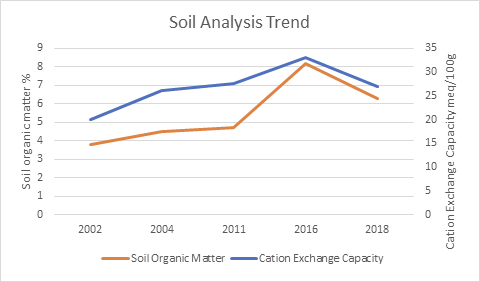

Below Black Barn field, Bottom Farm

The graph shows how the soil on our fields is improving in quality, by increasing in soil organic matter. To put this another way, we are actively absorbing CO2 out of the atmosphere and locking it into our soils. If this is repeated around the world, the benefits could be enormous; it has been estimated that agriculture could reduce global CO2 emissions by between 10% to potentially 30%. The graph also shows the increase in Cation Exchange Capacity (C.E.C). In basic terms as the CEC increases, there is more nutrition within the soil for the plants to grow healthily.

So, in the space of a few years of trying to work with nature, the results clearly show we are creating a healthier, more nutritious environment for crops to grow in. Not only is this good for the soil and the wider environment, but it is good for us also, as healthy soils grow healthy crops and healthy crops create healthy food for us to enjoy eating.

Learn more about our environmental credentials here and where to buy our LEAF Marque Cold Pressed Rapeseed Oil here.

I have been asked in the past what we do in the winter months. People comment, saying “Surely as an arable farmer, you plant the crops in the autumn, go away on holiday and come back the following summer ready to harvest them?” Nice thought, but I’m afraid the reality is a little different.

Admittedly, on an arable farm, where we only grow crops and do not have any livestock to look after, the winter months are quiet and it can be an opportunity to relax on a holiday if you wish. However, I have always found it the time of year for research, planning and projects, of which we have done many over the years. Back around the millennium, I remember spending many winter months researching the viability of creating a cold pressed rapeseed oil business on our farm, as a diversification project on something I found very interesting and to hopefully bring a little extra income to the family business. Looking back, I think this was time very well spent.

Of course winter is an ideal time for us to service all the farm machinery in preparation for the coming spring and summer months when we will want it to work long and hard without too many breakdowns. We have done many building projects over the years, both for new machinery ideas and for buildings on the farm. Some examples have been building a new trailer, or creating a water bowser. In the past, when I was a young boy and even before I was born, my Father and Grandfather were at their happiest creating new weird and wonderful machines in the farm workshop. Two of the most extravagant examples included a six-wheel drive tractor, converted from a World War II army fire engine. I remember going across the fields with them on this machine, before it finally over heated and was retired in the nettles. Their most famous project was when they took two normal tractors, replaced the standard engines with more powerful versions, before removing the front axils off both tractors and joining them together to make an articulated four-wheel drive machine, driven by one person from the back tractor. This was certainly cutting-edge engineering in its day, that was later copied and refined by machinery manufacturers in future years.

We have restored our beautiful traditional barns and converted them from redundant old farm buildings into offices, including our farm office today. New modern grain stores have been designed and built to cope with storing and drying the grain at the speed the modern combine harvester brings the crops in. Over the years, we have built all of the factory and some of the machinery inside it for Farrington Oils. Some of these projects seem to start as winter job ideas, but tend to stretch through other months of the year and before long take on a whole life of their own. The most recent being the latest expansion of Farrington Oils to create a new toilet and changing facilities, as well as extra space to mix our salad dressings and store ingredients. We have even made a little development kitchen in which Eli is currently very busy with her trusted jam jar creating some possible exciting new dressing recipes. This whole project started in April last year, we had a few weeks break for harvest to take place, before finally finishing the project just before Christmas.

Marvin planting saplings in Jan 2018

The other main type of project we have done during winter over the years is planting trees and hedges. We have literally planted thousands of trees and several kilometres of hedges since 1987 when my Father planted the first couple of spinneys on the farm. They are now well established, adding beauty and wildlife habitats to the landscape. This year we have been at it again. Marvin spent the time before Christmas with the chainsaw, thinning out dead wood from a copse area and old hedge, in readiness to replant with new young saplings in the first weeks of January. He has now created a few hundred more metres of hedgerow – Father and I have helped him with the spade to get some of the 2,000 hedge and tree plants put into the soil. We will have to weed around the young saplings for the first two years, after that they will hopefully grow and thrive, adding more beauty and wildlife habitat for many years to come. Additionally, we have a pile of wood ready to cut up for the fire to keep us warm at home next year.

Spinney on Bottom Farm that was planted in 1987, photo taken Feb 2018.

Although winter on Bottom Farm may not be spent on a combine harvester or tractor, it certainly is far from quiet!

Situated on the top of a hill, looking out over the city of Peterborough, Hill Farm Pick Your Own has been selling Farrington’s Mellow Yellow for over 3 years now. As a pick your own farm, they are one of our more unique customers and definitely one to be proud of.

Founded in the 1970’s, Hill Farm PYO started out when John & Jill Ivens bought the farm and decided to change it from a traditional arable and livestock mixed farm to a pick your own farm, growing fresh produce and allowing the public to pick it themselves. They started off with sweetcorn and expanded into raspberries, then strawberries and all the other produce that can be found today. Hill Farm is now run by John & Jill’s son, Paddy, and his wife, Susannah. They grow an incredibly wide variety of fruits and vegetables, with the aim of extending the picking season so you can enjoy fresh, hand-picked fruit and veg for even longer. Strawberries have remained the best selling fruit each year, in fact most people know it as ‘the strawberry farm on the hill’, but pumpkins are now gaining popularity and are the second best seller. With the farm decorated with ghosts and pumpkins in all shapes and sizes, it’s not hard to see why people continue to flock to the farm in the cold of October.

We visited Hill Farm about a week into July, when there would normally be row upon row of strawberry-filled plants, however, due to the unexpectedly hot June we had this year, they were down to their last two varieties! This is one of the excitements of farming, so much is down to the weather. This year, everything has ripened at the same time rather than being spread out over the summer months. However, hidden in the rows there were still plenty of strawberries ripe for the picking!

A few years ago, pick your own had a bit of a dip in popularity, but now it is definitely back in fashion and incredibly popular as a family day out. Susannah says that it takes people back to the old way of cooking; using seasonal vegetables when they’re available. Some people even visit the farm and pick buckets of fruit to be frozen and last them the entire summer.

Keeping the crops healthy is very important. Hill Farm PYO run on a 3 year crop rotation which helps maintain the soil and keep the fields producing the very best fruit and vegetables. As well as their crop rotation, Susannah and Paddy make sure that there is a daily inspection of the fields and that a different field is picked each day.

In addition to pick your own, Hill Farm also has a shop which sells a selection of pre-picked produce as well as local products, which is where we come in. Our full range of products is available on a beautiful stand behind the counter, and they tend to sell lots of our rapeseed oil later on in the year as it is perfect for when the squashes are in season. In fact, we have a brilliant recipe for squash season: http://farrington-oils.co.uk/recipe/chilli-chorizo-butternut-slice/ .

Hill Farm Pick Your Own is open from June to the end of October, so if you’re nearby it is definitely worth a visit this summer, just remember to call ahead to see what is available for picking each day. Website: www.hillfarmpyo.co.uk, phone number: 01733 233270.

Here at Farrington’s, we don’t use neonicotinoids on our rapeseed crop. This is for many reasons, mainly because of the concerns related to this pesticide and the effect on bees. You can read more about our bee friendly rapeseed and what else we do to keep the bees on our farm healthy and happy here.

Friends of the Earth, a campaign group looking for solutions to environmental problems, is concerned about the impact of neonicotinoids on bees and other pollinators and urged farmers to join them in pledging not to use neonicotinoids. We were asked us to join the Bee Friendly Shoppers Guide to Rapeseed Oil, of which we are 1 of only 7 rapeseed oil producers on this list. Of course we said yes! The guide aims to educate shoppers on which oils to buy, and how these oils are helping Britain’s bees. As part of the guide, we have pledged not to use the three neonicotinoid pesticides which are currently restricted across the EU, and will continue to avoid these pesticide even if the ban is lifted.

The Bee Friendly Shoppers Guide to Rapeseed Oil is supported by a number of leading chefs. These include Kevin Gratton, chef director for Mark Hix Restaurants, David Everitt-Matthias of Le Champignon Sauvage, Martin Burge, executive chef at Whatley Manor Hotel & Spa and Tom Hunt, eco chef owner of Poco Tapas Bar. Friends of the Earth, alongside the supporting farmers and chefs, are asking consumers to support the initiative by buying the bee-friendly rapeseed oils detailed in the guide.

Friends of the Earth’s Bee Campaigner, Nick Rau, said “We’re delighted Farrington’s Mellow Yellow is standing up for Britain’s bees by pledging not to use these three bee-harming pesticides on their rapeseed crops. They deserve our support. We hope more farmers and producers follow their lead and say no to these neonicotinoid pesticides. Nature-loving shoppers can back this pioneering initiative by checking out the Bee Friendly Shoppers Guide to Rapeseed Oil and choosing these products in supermarkets, local stores and online.”

To read more about the Bee Friendly Shoppers Guide to Rapeseed Oil, please visit: http://www.rapeseedoilguide.com/

Back in 2012, thanks to the growing success of Farrington’s Mellow Yellow we started using rapeseed from a second farm, working with our neighbours, in addition to the seed we grow on our own farm. See my blog; “Mellow Yellow Popularity Grows” April 10, 2012. Now, we have added a third farmer to the list.

The Bletsoe and Farrington families have been neighbouring farmers since at least my great grandfather’s day. Like most farming neighbours, we have developed strong friendships over those generations, built on trust and the odd bit of occasional light hearted banter.

Emma Bletsoe has, for several years, used our rapemeal, produced as the by-product from pressing the oil out of the seed, to feed her cattle. Then a couple of years ago, Emma and I were chatting at a local gathering, when the conversation moved on to her rapeseed crop and my future needs for more LEAF Marque rapeseed. Emma thought that as well as buying the meal off us, perhaps she could also sell us her seed in the first place. Emma and her guys on the farm, Garry and Stuart, have worked hard to meet the rigorous LEAF Marque standards, which they passed with flying colours.

Now we purchase seed from Emma, which ensures I have a fully traceable, accredited supplier; while Emma gets a little bonus and the odd bottle of oil for the extra work required. Then once we have pressed the seed to produce our Mellow Yellow, Gary or Sturt arrive with their tractor and trailer to collect the rapemeal, which they use to make a healthy and, again fully traceable, meal for their cattle. This is something the cows particularly like in the cold winter months when they are kept in warm straw-bedded barns, as opposed to eating fresh grass in the fields during the summer.

This is a prime example of neighbouring farmers working well together, making happy farmers, happy cows and most importantly, the best quality, delicious Farrington’s Mellow Yellow that you can trust every time.

Neonicotinoids insecticides hit the headlines because their use for controlling cabbage stem flea beetle in crops of rapeseed and the suspected links to declining numbers of honeybees and native bumble bees. At Farrington’s we have more questions from our valued customers about this, than any other topic. Before I go any further, just to confirm we are growing bee friendly rapeseed, we do not use Neonicotinoids in growing our rapeseed and do not intend to if the ban is lifted.

How we grow our crops and look after the wider environment has always been my top priority at Bottom Farm. Indeed, I joined LEAF (Linking Environment and Farming) back in 1997 to learn more about doing the right thing in this area.

Why is Cabbage Stem Flea Beetle such a problem?

Rapeseed plants grow from the tiny little black seeds planted at the end of August each year. The first few weeks are vital in the survival of the crop, which requires a warm, moist soil to help it germinate and tentatively put its head above the surface, from which the tender young plants start to grow. However, these young tender plants are delicious to a number of predators including flea beetles. So much so that if the conditions are right for flea beetles, they can completely wipe out a crop overnight. After which it is often too late to replant a second crop of rapeseed, as the soil temperature has dropped below the minimum required for the plant to grow.

What is a Neonicotinoid?

Neonicotinoids are a group of insecticides based on nicotine. In rapeseed, the chemical is coated in tiny amounts onto the seed to be planted and moves (is translocated) into the growing plant as it emerges from the soil. When a flea beetle nibbles on said plant, there is just enough of the toxic chemical to kill the pest. But otherwise, it is a specifically targeted use of an insecticide in an ingenious way.

Concerns grew that numbers of both honey bees and bumble bees were declining, so scientists explored the potential causes. It appears there are several possible causes including; loss of habitat for bees to feed on and live in; potential pests and diseases affecting bees, such as Varroa mite; changing weather patterns, such as cool damp springs; use of agricultural pesticides.

Some research suggested that small amounts of Neonicotinoid translocated through to the pollen and nectar in the flowering rapeseed plants. When bees visited these flowers they were inadvertently ingesting the chemical which was causing them to lose their bearings; a bit like us trying to find our way home after having too much of a good night in the pub. Other research suggested longer term damage to the fertility of the bee colony.

Although research appeared inconclusive with the debate on both sides being passionate, the EU restricted the use of Neonicotinoids on rapeseed crops from 2013, until such time that more conclusive evidence is shown.

Growing Bee Friendly Rapeseed.

I use several approaches to try and grow a successful crop of rapeseed whilst looking after our bee populations.

– I use a crop rotation and have extended the rapeseed from one in 3 years, to one in 4 to 5 years. This will provide a bigger gap between the crop so as there is less food around for the flea beetle to live off, that will hopefully in time reduce the risk of attack.

– Established wildflower meadow areas around the farm to create a perfect habitat with a variety of pollinating plants for bees and other beneficial insects to live off.

– Planting the crop into fertile soil, with the use of a healthy crop rotation which includes nutrient building cover crops to give the rapeseed the best possible chance to grow quickly out of the danger period when it is susceptible to flea beetle damage. This is backed up with a small amount of fertiliser if required.

– A local beekeeper has hives on the farm. The bees help fertilise our rapeseed and other crops, making delicious honey in the process.

– I am experimenting by growing companion crops of vetch and clover within the rapeseed. These create a friable soil structure and add nutrition to help the rapeseed plant grow well. It may also confuse a passing flea beetle as to what crop is actually growing in the field and may pass by unaware that their favourite meal is below them.

– As a final resort, we use an insecticide as found in head lice shampoo to kill bad infestations of flea beetle. If we use this, we make sure we spray the crop early in the morning or late at night, as the flea beetle will still be feeding on the crop, but the bees are all tucked up in bed.

In Summary, this hopefully explains some of the conundrums I have as a farmer in trying to do the best thing. Hopefully also, as I write in December 2016, with a temperature of -4.5°C this morning, I am confident that nature will help us enormously in reducing the number of flea beetles surviving the winter.

After nearly ten years, my monthly ramblings of life as a farmer, initially for a local village magazine and latterly for the Evening Telegraph; must come to an end as I need to spend more time helping our growing business.

Ten years ago, the economics of agriculture were not that inspiring and I was just starting out in a diversification project as Britain’s first person to grow, press and bottle rapeseed oil. In my mind this was going to be a small project to help supplement income from the farm, enabling Eli and me and, our young family to remain living and working on the farm. Little did I realise, that Farrington’s Mellow Yellow would become the success it has.

Within four years, Farrington Oils outgrew the farm in turnover. I had to start employing people and with it, learn very quickly how to find the right team to work with, as well as how to work with our increasing number of customers and meeting the many loyal consumers who buy our products that keep us all in business. I am very proud of the fact that in our little village of Hargrave, we now employ over 15 people. We have a fantastic team who are just as passionate about what we do here as I am.

There are many UK farmers now replicating what I started, of which there are three main brands, with us in the top two. However, while the success has been obvious, it is not the time to slow down resting on our laurels’. Competition is fierce keeping us all on our toes. As the market for cold pressed rapeseed oil matures, it is more important than ever to keep pushing forward, because if I don’t, others will and they could take our market. We are now looking for new customers both in the UK and abroad. I am delighted we are now; ‘exporting oil to the Arabs’ – its only small at the moment, but will hopefully grow, especially when Eli and I attend an international trade show in Dubai next February for example.

Closer to home as we need to travel the country visiting customers here, I have just invested in our first company car. To keep in line with our cool British credentials, it had to be a Mellow Yellow Mini from the local Mini dealer in Northampton and I love it. Mini is a successful British brand exporting 80% of what it produces, whilst this may be a tall order for Mellow Yellow, it is certainly something to aim for over the next few years. Look out for our soon to be branded Mellow Yellow Mini on the roads.

Thank-you to all of you who have read my diary over the last ten years, I can’t believe you could have put up with me complaining about the wrong type of weather on so many occasions. I have thoroughly enjoyed writing my diary and meeting so many readers over the years. I wish you all a very Merry Christmas and all the best for 2016.

Day 32 in this year’s harvest and exhaustion has taken over from adrenalin. After an initial rain interrupted false start, the rape harvest went without a hitch, which despite the lack of rain in the months before, produced a pleasing ‘good average’ result. Following the rapeseed, we moved straight into to some early wheat on light land that had died a premature death from lack of moisture. This also flew by in record time, although the low yield had something to do with the speed we moved across the acres. Everything went to plan, no machinery breakdowns, long dry days and plenty of packed lunches and supplies to keep us going for two weeks without a stop, clocking up more hours than I like to think about.

Following the early wheat, we then had to be patient and wait for the next bit to mature. The weather was still perfect for combining, many neighbours were at it, but we had to wait a few more days. This is frustrating, as with experience the weather will change at any time. In theory, we only had another two weeks of combining and it would all be done for another year.

Finally, the wheat was just about ready, we combined one field with a very pleasing yield on our heavy land that I would not have expected only a month earlier. Then the rain arrived. The weather reports say the Jet Stream has gone south and our island nation is stuck between a high and a low-pressure system battling it out; the result being a prolonged period of sunshine and showers. All pretty standard, but frustrating never the less. We have now finished all of our winter wheat, combining as soon as the conditions allow, in a stop-start fashion resulting in us harvesting the same hours in a week as we were doing in a day at the start of harvest.

When conditions are like this, it is difficult to keep the adrenalin and motivation going, having to ensure we are absolutely ready in the right place when conditions are right. Late one Saturday night we needed to move the combine 300 metres from one field to another when a tyre blew on a trailer. Quickly Marvin and I got the compressor and tools to try to repair the tyre, but could soon see it was not going to happen. Rain was due the next day and we wanted to keep going. Time for blocks of wood and the forklift, and we were able to drag the trailer to the next field so the work could continue a bit longer.

We still have another few days worth of harvest to do, but I don’t know when we will get these days as August now turns into September. Father, Marvin and I have worked hard over the last month, we are all getting a little tired and some may sit grumpily at times. It is standard procedure and something long-suffering farmers’ wives and families have to put up with on an annual basis. Something I try to remember, as, without the support team in the background, the job would be impossible.

Oils

Oils Rapeseed Oil

Rapeseed Oil Chili Oil

Chili Oil Dressings

Dressings Blackberry Vinaigrette

Blackberry Vinaigrette Classic Vinaigrette

Classic Vinaigrette Balsamic Dressing

Balsamic Dressing Honey & Mustard

Honey & Mustard Ultimate Chilli Dressing

Ultimate Chilli Dressing